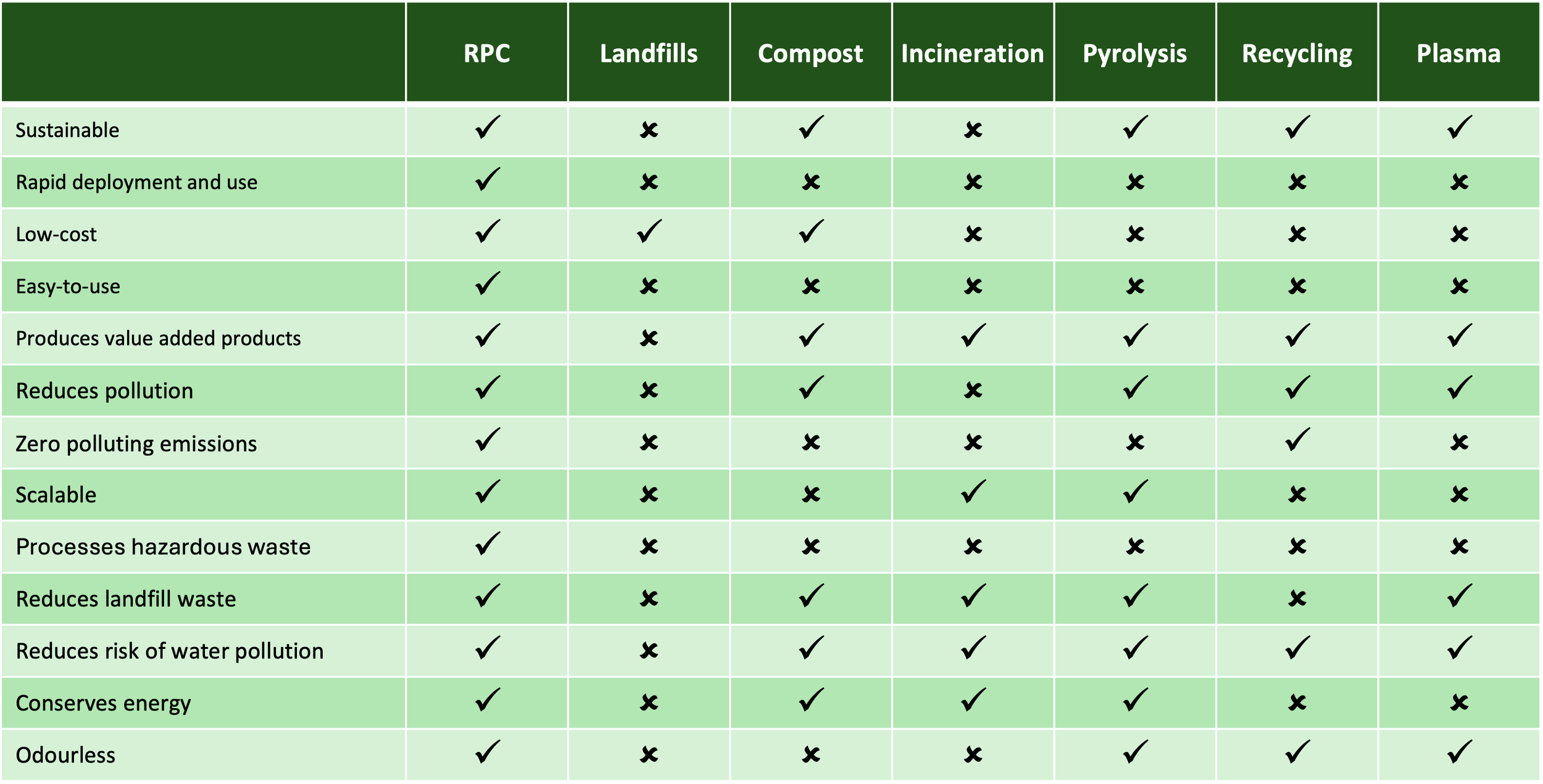

Our Competitive Advantage

PROBLEM

Our global community is producing an increasing volume of waste of all kinds, and the traditional methods of either burning or burying it are no longer viable.

Landfills take up large areas of land, create dangerous off-gas, air pollution, and toxify the soil and ground water.

Incineration, the most popular global ‘waste to energy’ alternative to landfills, present high cost of capital investment, and produces toxic emissions such as dioxins, furans and other greenhouse gases[1]. This is despite the latest technology.

Pyrolysis is complex and expensive, resulting in low efficiency, and it releases significant greenhouse gas emissions[2].

Recycling, while a step in the right direction, has proven itself to be ineffective as a complete solution.

Plasma Gasification is highly technical, expensive, and so far has demonstrated marginal profitability.

THE WASTE MAGIC SOLUTION

The Rapid Pulse Carbonisation (RPC) process is:

Environmentally Super-Friendly - Zero emissions, distilled water and carbon black are the only by-products.

Efficient -

The process is based on a traditional autoclave, these are fast, easy, and cost-effective to manufacture.

At heat and pressure the waste is combined with approximately 100mls of RPC’s chemical catalyst, which is also easy and low cost to create.

Initial estimates indicate 240kW of power to process 30m³ (10 tonnes) of waste.

A complete cycle including loading and unloading is estimated to take 90 minutes. Machines will be able to run continuously with 2-3 days per month for maintenance.

One operator will be able to operate 2-3 machines.

Scalable - The initial 30m³ machines will be run in parallel for continuous operation. Larger machines will be produced for specific high-volume projects, as will smaller machines for needs such as medical waste.

Commercial - Waste Magic receives three revenue streams; tipping fees for receiving the waste, carbon credits for its zero emission process, and revenue from the sale of the carbon black (N110). The carbon black output will also be able to be cost-effectively refined to higher quality grades of carbon black, and potentially graphene in the near future.

[1] Sage Journals, 2022 Abstract

[2] Zero Waste Europe, 2022 Case Study